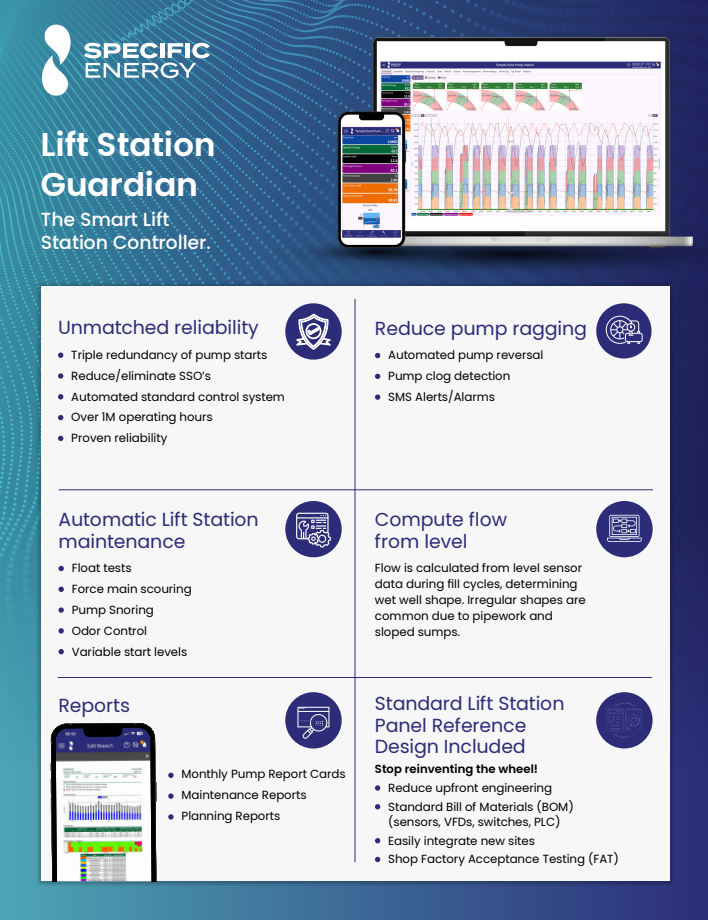

LIFT STATION GUARDIAN

The smart lift station controller.

“The Lift Station Guardian is a standardized product that is easy to commission, scales with our growth, and makes sure our lift stations operate correctly. We are installing the Lift Station Guardian on every new lift station.” - Aldo Zamora, Operations Manager for Mustang Special Utility District

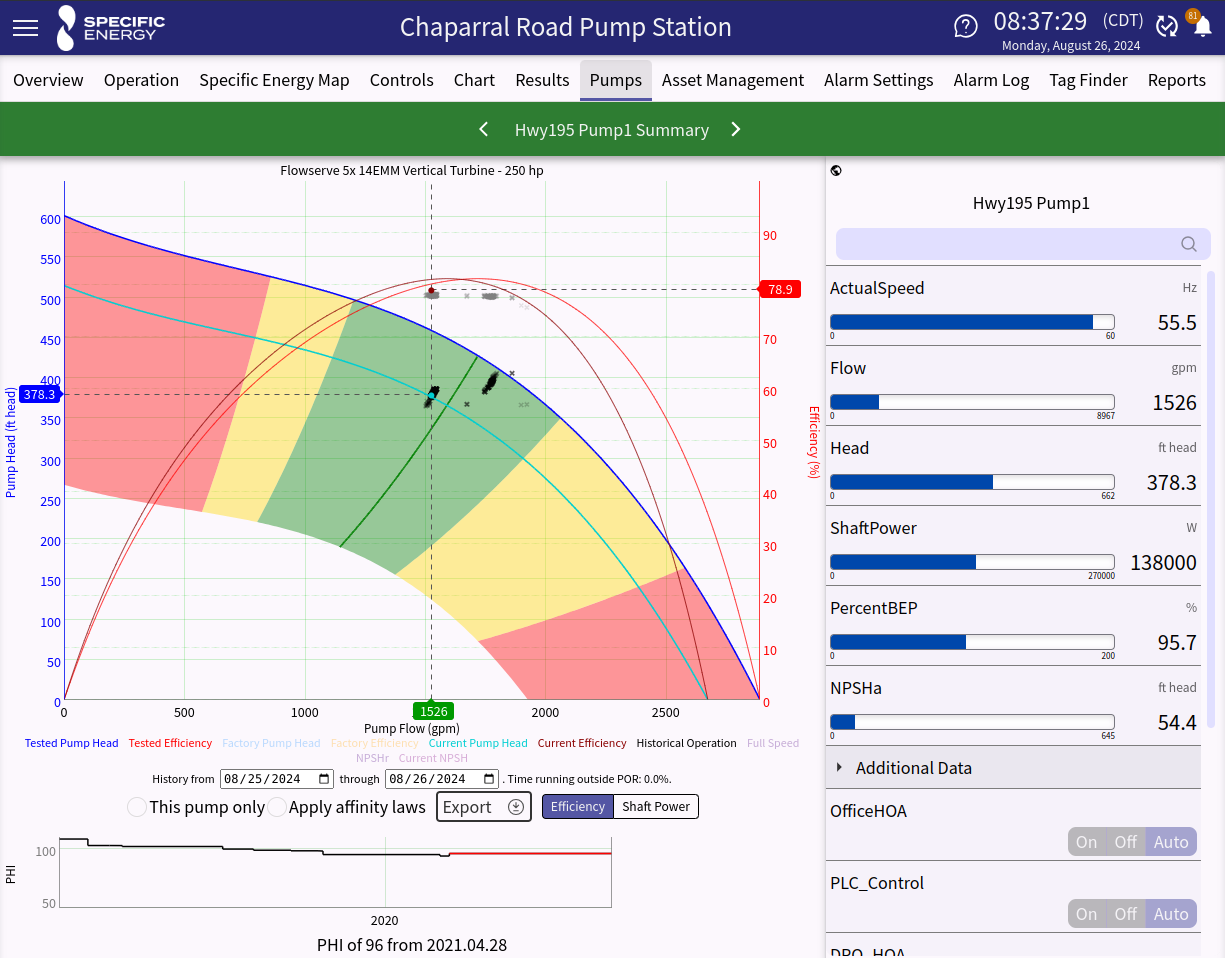

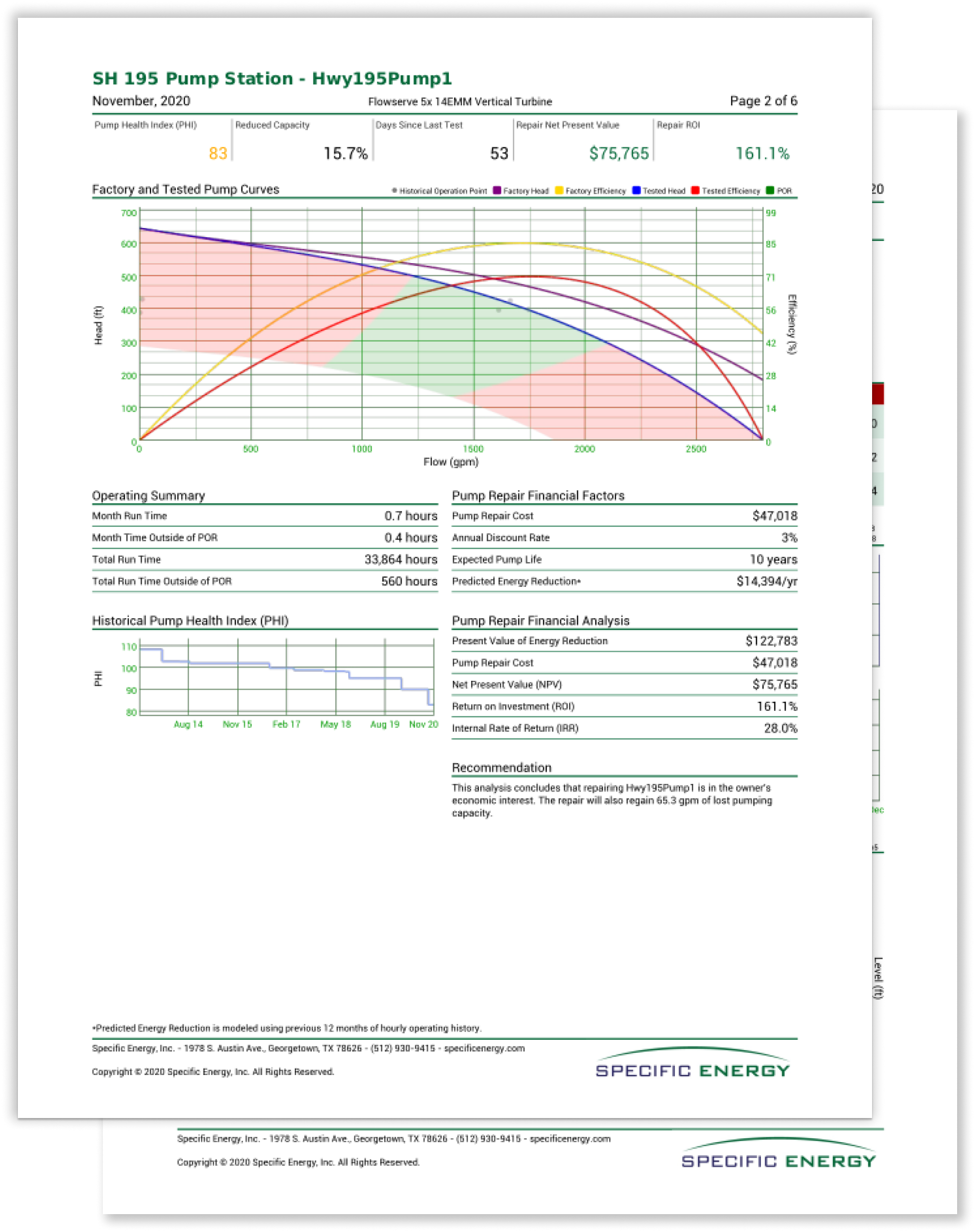

TRACK PUMP HEALTH

Save your pumps.

Track pump health over time to make maintenance decisions based on energy savings from repairing or replacing a pump. Using flow data, real-time pump curves are generated and compared to factory pump curves to determine any loss of efficiency or capacity.

Get a snapshot view of pump health, operating summary, energy usage, and the net present value of repairs from reports that get automatically sent to your inbox.

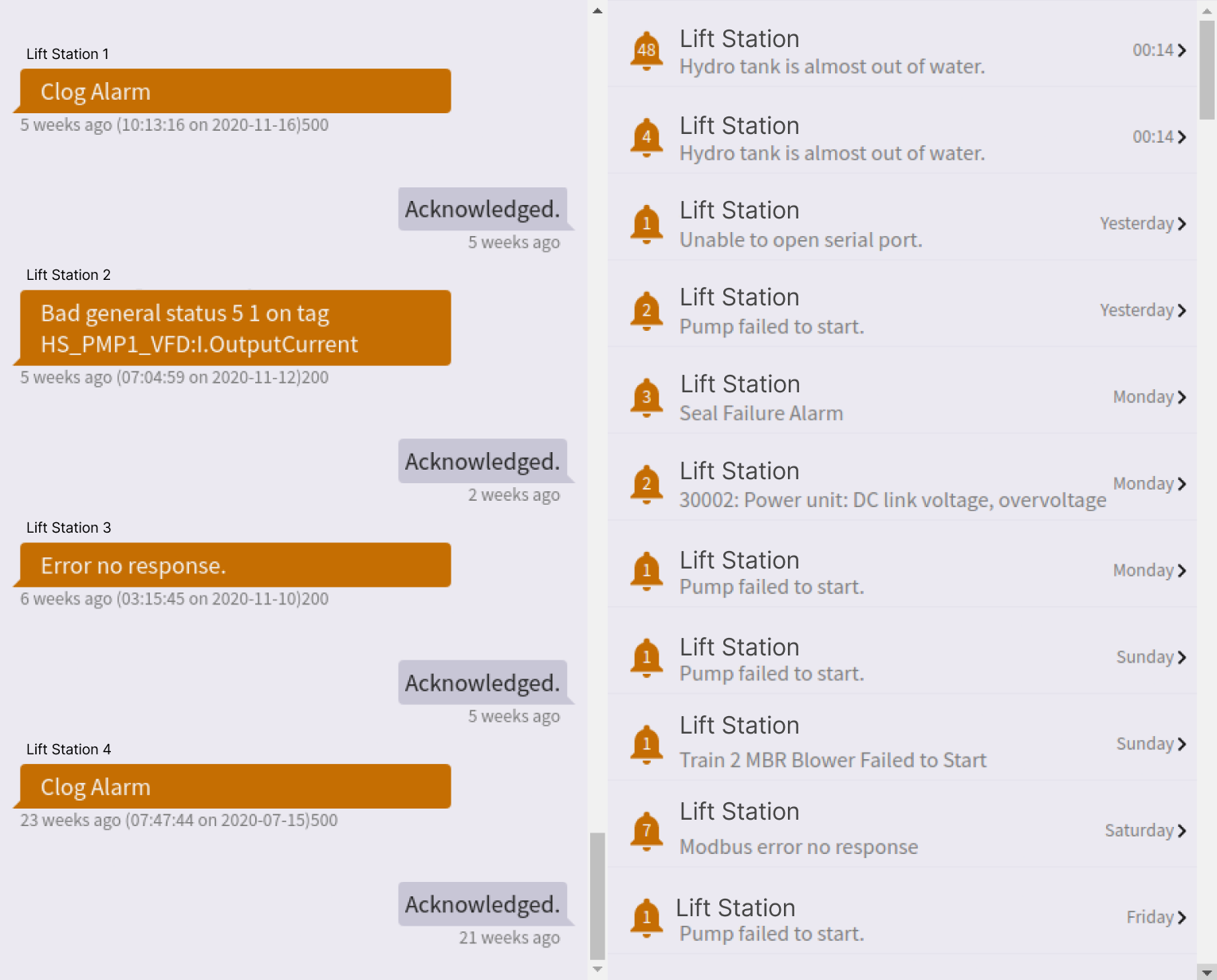

ALARM & EVENT ENGINE

Get notified.

Adopt the easily configurable and fully customizable alarm system so that you see alarms you want to see. Alarms can be tailored to fit the constraints of a system so that nuisance alarms can be quickly filtered out.

Alarms are sent via text message with a link that takes the user directly to the problematic site or can be viewed through the alarm interface on Specific Energy's cloud based analytics platform.

PLANNING & ANALYTICS

Plan for expansion.

Generate planning reports that show station rated capacities, peak dry weather demands, peak wet weather demands, and under or oversized lift stations to determine if additions to the system are needed to accommodate expansion.

Export an unlimited amount of data to perform custom analysis to meet your planning needs. The cloud based interface enables export of large amounts of data for given time frames and combinations of logged data.

-

Generate planning reports

-

Track seasonal demand changes

-

Compute station capacities

-

Identify inflow & infiltration issues

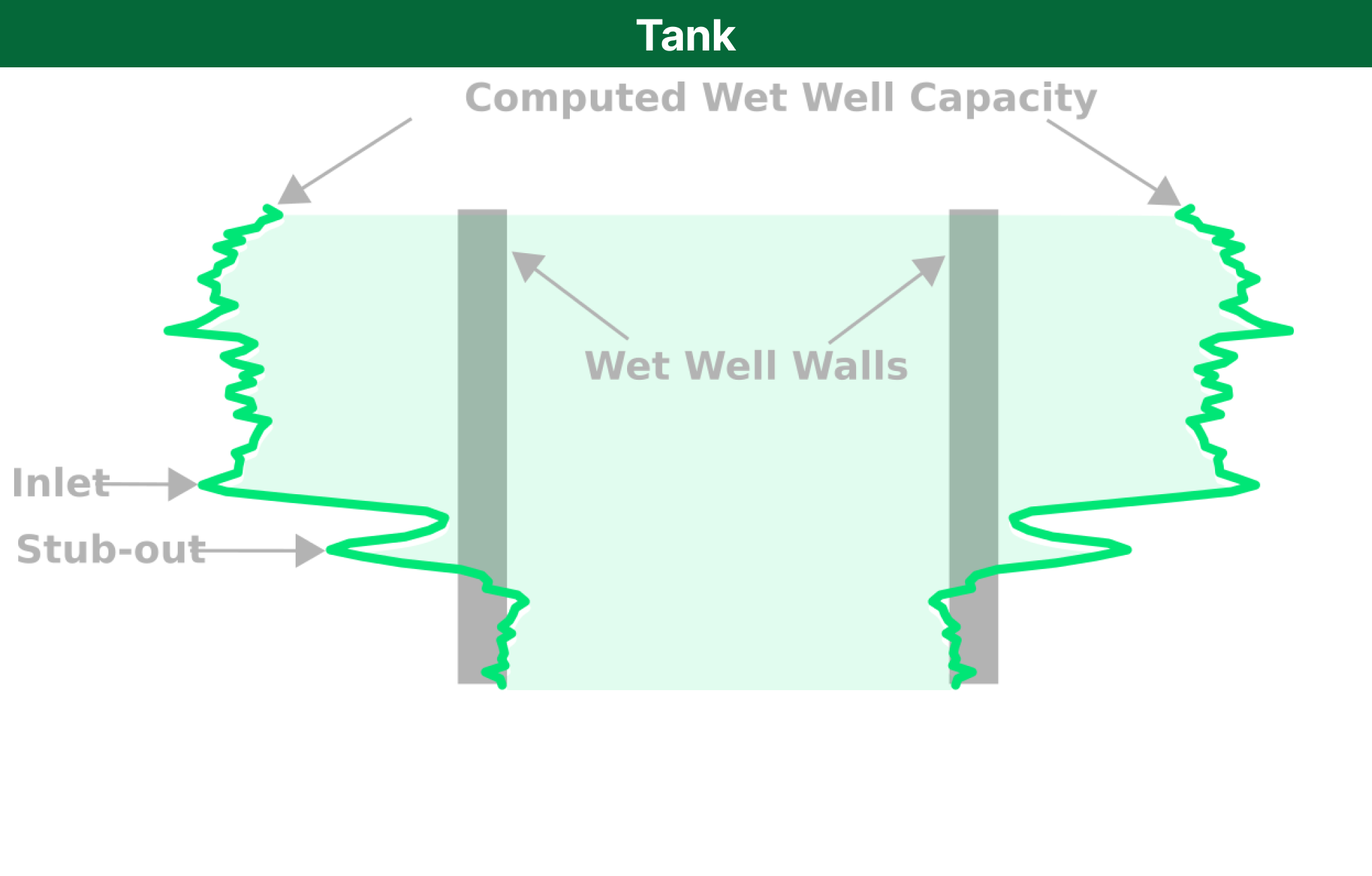

ACCURATE INFLOW & OUTFLOW

Compute flow from level.

As a low cost, high-accuracy alternative to the added expense and maintenance of installing a traditional flowmeter, volumetric flow calculations give insight into the health of a lift station and the overall waste water system. The volumetric flow-meters are automatically re-calibrated weekly.

The shape of the wet well is derived from level sensor data collected during fill cycles to calculate flow from the volumetric change over time. Wet wells tend to have irregular shapes due to stub-outs, inlet pipes, emergency suction lines, and sloped sumps. These irregularities, and more, are accounted for in Lift Station Guardian’s flow calculation.

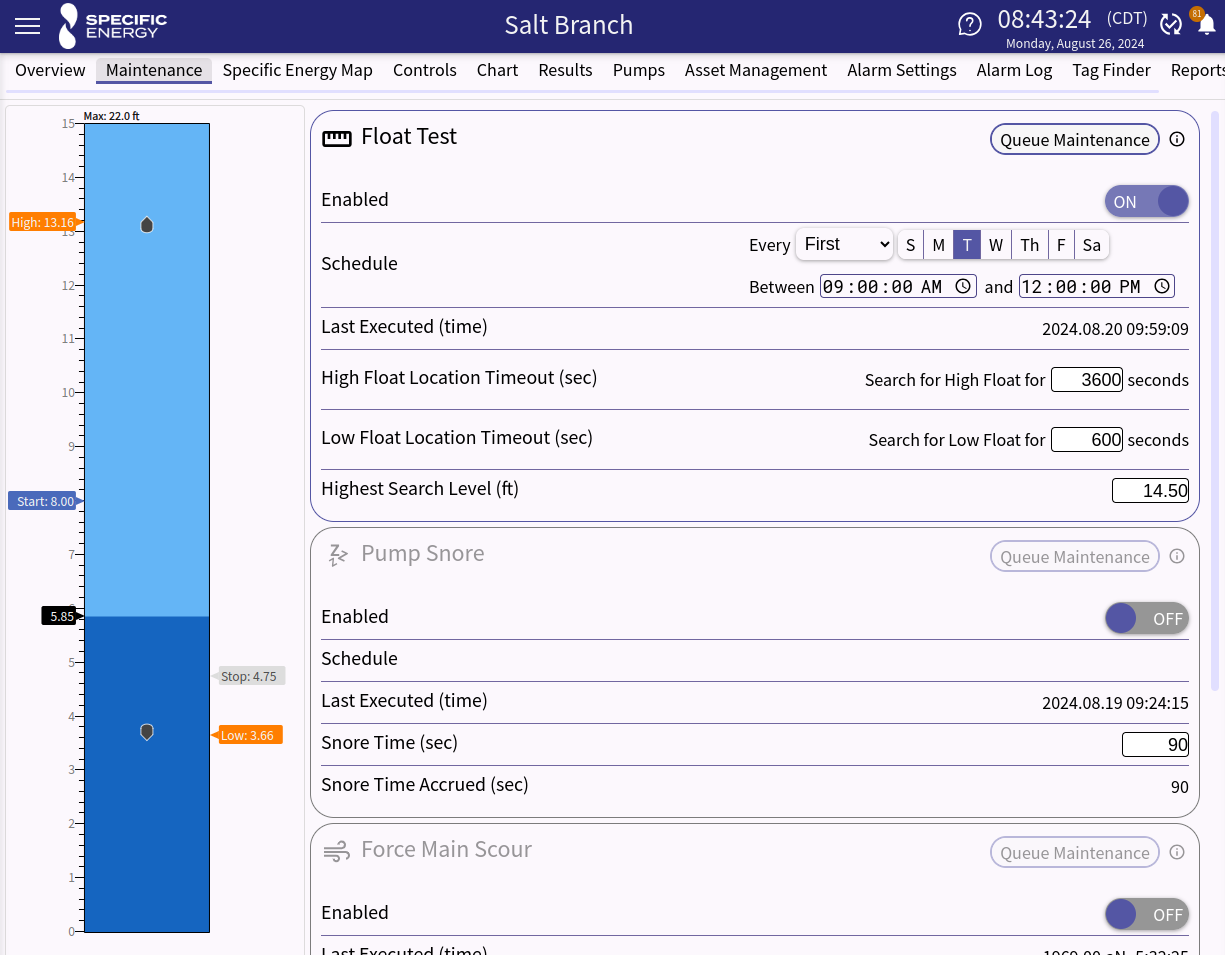

SIMPLIFY MAINTENANCE

-

Maintenance Reports

Generate maintenance reports on the fly and distribute them to maintenance crews to tackle outstanding issues. Maintenance reports include identified issues with sensors, floats, pumps, check valves, sediment buildup, I&I issues, and more.

-

Float Testing

Periodically allow the wet well level to reach the various float positions and receive a notification if a float fails to signal an alarm.

-

Force Main Scouring & Pump Snoring

Schedule Lift Station Guardian to automatically perform force main scouring and pump snoring so that you don't have to.

-

Clear Pump Clogs

Identify and report pump clogs by observing changes in amperage and flow.

-

Track Inflow & Infiltration

Generate maintenance reports on the fly and distribute them to maintenance crews to tackle outstanding issues. Maintenance reports include identified issues with sensors, floats, pumps, check valves, sediment buildup, I&I issues, and more.

FAST COMMISSIONS

Ease of installation.

Enjoy rapid commissioning and configuration from your smart phone. Simply answer a few questions about a station to fully commission the Lift Station Guardian control panel.